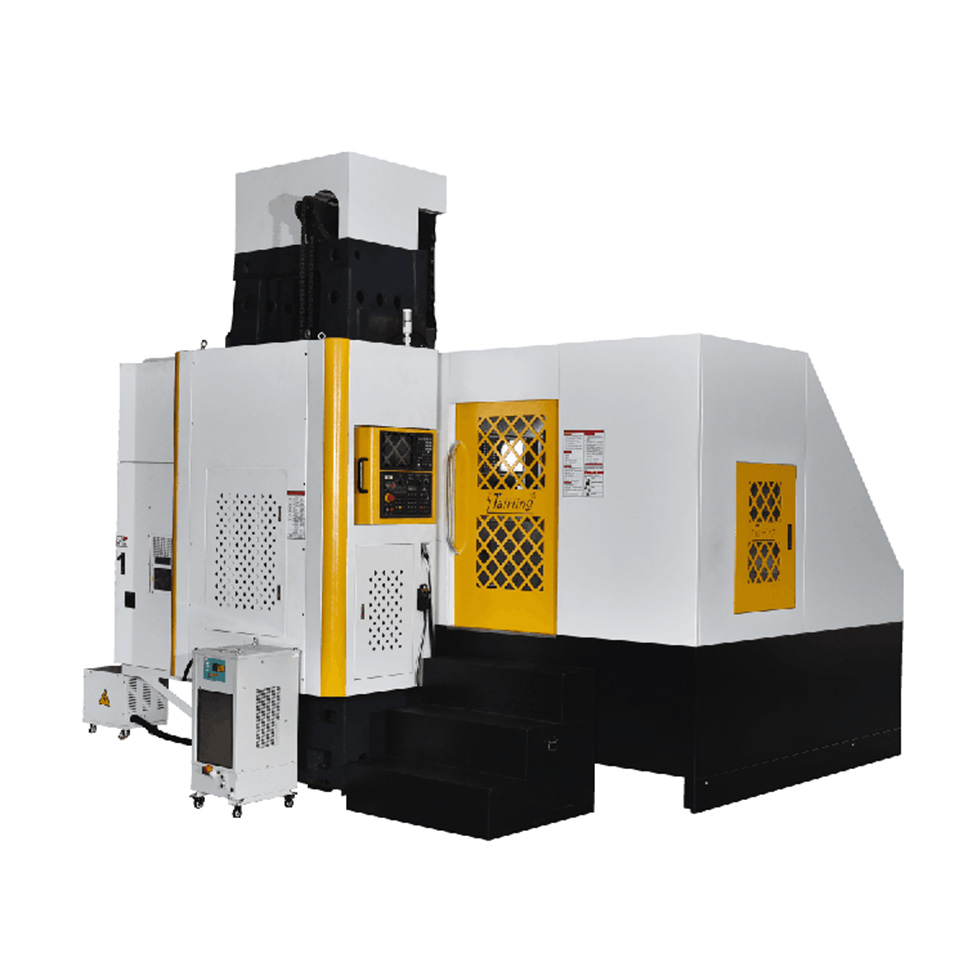

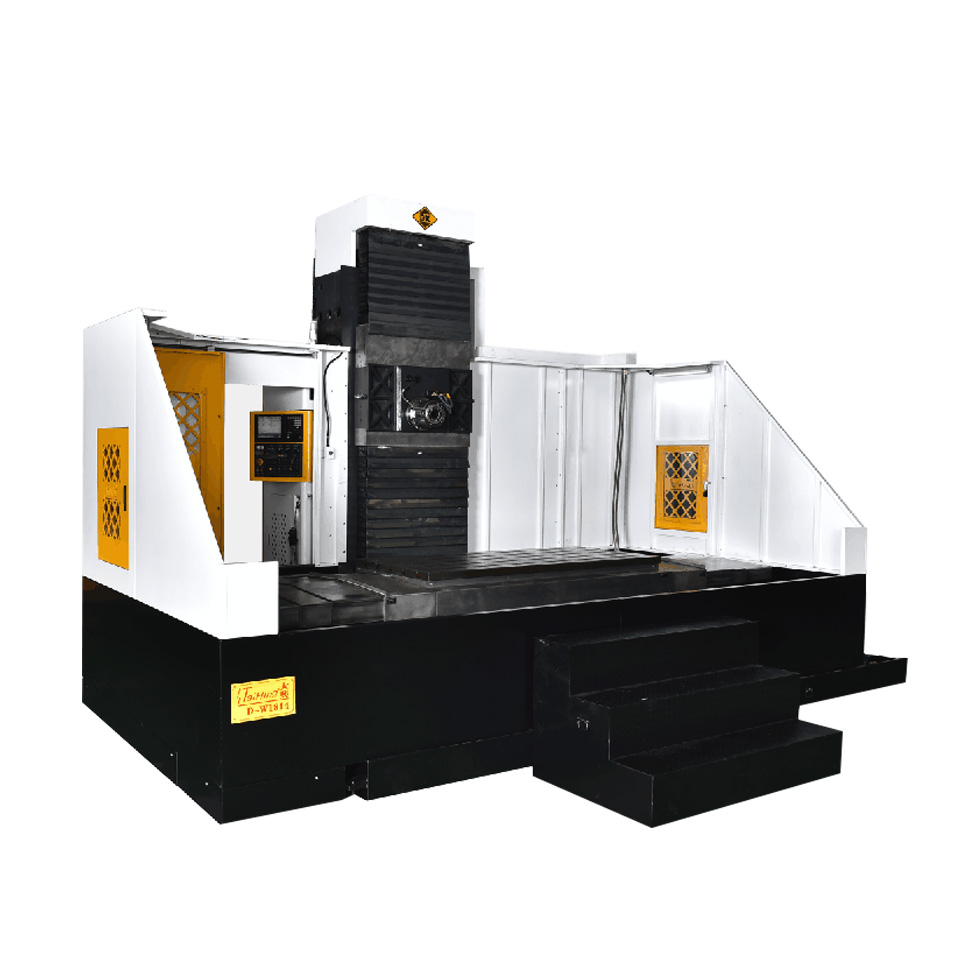

Mechanical characteristics: Horizontal machining centers have high structural rigidity, stable performance, and good market cost-effectiveness, making them the preferred product for users to purchase horizontal machining centers The base of the machine is designed with an inverted T-shaped structure, which has high structural rigidity and is supported by sliding guide rails. The gantry shaped column, high rigidity saddle, and strong spindle head reflect the high rigidity and strong capability of the machine tool The spindle transmission system has a servo motor that is directly transmitted to the high-precision spindle through a synchronous belt, which has the characteristics of high transmission efficiency, low noise, and low vibration, making the output power of the spindle constant and improving processing efficiency. The spindle is a key component in cutting machining, and this machine tool designs the spindle based on the structural characteristics of the machine tool. And entrusted to Gu Wan's professional manufacturer for production, ensuring high rigidity, high speed, and high precision of the spindle Anti collision design can prevent the nut seat from directly colliding with the motor seat and bearing seat when over travel occurs, ensuring that abnormal machine tools can damage the mechanical and machine tool accuracy

15989519333 (Mr Xu)

Online consultation Message consultation

Main specifications and technical parameters

| Main technical parameters |

||||

| Mechanical specifications |

name |

Specifications |

Company |

|

| trip |

X-axis travel |

2500 |

mm |

|

| Travel Y-axis |

1500 |

mm |

||

| Z-axis travel |

1000 |

mm |

||

| Distance from spindle nose to workbench center |

370-1370 |

mm |

||

| Distance from spindle center to worktable |

300-1800 |

mm |

||

| workbench |

Workbench size |

2700×1200 |

mm |

|

| maximum load |

55000 |

kg |

||

| T-shaped groove (number of grooves - size - spacing) |

7-22-170 |

mm |

||

| principal axis |

Spindle speed |

6000 |

rpm |

|

| Main spindle tool holder form |

BT-50 |

|||

| Spindle diameter |

Ø190 |

mm |

||

| Transmission mode |

Belt type |

|||

| Feed rate |

Fast moving speed X/Y/Z |

10 / 12/ 12 |

m/min |

|

| feed rate |

1~8000 |

mm/min |

||

| Machine accuracy |

X/Y/Z-axis positioning accuracy |

±0.005/300 |

mm |

|

| X/Y/Z axis repetition accuracy |

±0.003 |

mm |

||

| motor |

Spindle motor |

15 |

KW |

|

| X. Y and Z-axis drive motors |

6.0/6.0/6.0 |

KW |

||

| Oil pump |

DY-YBM-1100 |

1100W |

||

| Tool magazine (optional) |

Tool magazine capacity |

24 |

branch |

|

| Automatic tool change type |

Circular blade arm type |

|||

| Knife handle specifications |

BT-50 |

|||

| Knife handle pull nail |

45 |

degree |

||

| Maximum tool length |

400 |

mm |

||

| Maximum tool diameter |

Full of knives |

Ø110 |

mm |

|

| Neighboring empty knife |

Ø200 |

mm |

||

| Maximum tool weight |

18 |

kg |

||

| Tool change time |

2-5 |

sec |

||

| Land occupation space |

Mechanical height |

3500 |

mm |

|

| Floor space (length x width) |

6000*5800 |

mm |

||

| Mechanical weight |

18000 |

kg |

||

| Total electrical capacity |

50 |

KVA |

||

| Pressure demand |

0.5 ~ 0.8 |

MPa |

||

Processing applicationsProcessing application

Mold cutting, mold frame, cavity, motor housing

Efficient/ReliableHigh Efficient and Reliable

※ Quick movement X Y, Z: 30/30/30m/min (HPC650) three-axis standard cooling mechanism, simple structure, maintenance free

※ ATC tool change time: 2.5S (tool to tool) The servo tool library has a tool waiting position, which can be quickly changed through a cam type robotic arm. It can recognize heavy tools weighing over 20kg, making tool replacement stable and reliable.

High speed APC exchange time of 10 seconds, frame lifting structure, motor driven to achieve rotary exchange of workbench, fast and reliable.